Full Sheets

PRODUCT DESCRIPTION

Basic Use:

Fiber insulation used for acoustical control, providing a high-impact tackable panel or wall surface, including thermal insulation.

Benefits:

It is a lightweight, durable, impact resistant and a semi-rigid substrate. It is fabricated from 100% polyester with no irritating fibers, free of volatile organic compounds (VOCs), including formaldehyde. It resists bacterial and fungal growth, while being non-toxic and non-allergenic. It will not rot, deteriorate, or change color over time. The product can be easily fabricated on the job site using standard tools

Composition and Materials:

Manufactured from 100% polyester fibers thermo-bonded together to achieve the desired thickness and density. It has a 60% post-consumer content (recycled plastic beverage containers). It is 100% recyclable.

Sizes:

4′ X 8′

Thicknesses 12mm and 24mm Quarter and full sheets, custom sizes available in all colours.

Densities:

12mm and 24mm – 9.4 PCF

TECHNICAL DATA

Applicable Standards:

• BOCA, ICBO, SBCCI, CASO, ICC

Fire Resistance:

• ASTM E84, UBC 8-1, ANSI/NFPA 101 CAN/ULC-S102

Maximum Flame Spread Index:

12mm – 5; 24mm – 20

Maximum Smoke Developed Index: 12mm – 70; 24mm – 195

Physical/Chemical Properties:

• Acoustical Performance ASTM C423 (See Table)

• Water Vapor Sorption:

< 0.4% by weight- Non-hygroscopic

• Weather Resistance:

No change in appearance/durability

INSTALLATION

Eco-Felt can be directly applied to drywall, concrete, CMU, or other ASTM E 84 Class A materials. It can also be cut and installed using standard tools.Additionally, Eco-Felt can be used as a componentof pre-made acoustical and tackable panels, modular panel systems, ceiling tiles, baffles, and cloud diffusers.

Specifications

| Product Name | Eco Felt |

|---|---|

| Composition | 100% polyester fibre |

| Edge Detail | Square edge |

| Fire Rating | ASTM E84 Class A CAN/ULC-S102.2-10 |

| VOC Emissions | CDPH (CA 01350) |

| Antimicrobial Testing | Mould & mildew resistant |

| Sustainability | 100% recyclable LBC Red List free Contributes to LEED certification Free of toxic substances and of off-gassing Made with ~60% recycled content from plastic water bottles |

| How to Specify | Product Name & Code Dimensions Colour Installation Method |

| Colour & Texture Variations | The felting and dyeing process that forms the material contributes to its unique texture but also to variations in texture and colour from panel to panel. Products will be provided within an acceptable range of variation. |

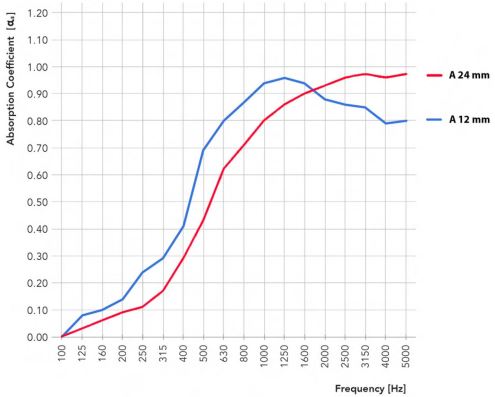

Acoustic Properties

The following values reflect the acoustic properties of the product as tested in accordance with ASTM C423-09a using Type A mounting.

| NRC | SAA | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A12mm | 0.55 | 0.54 | 0.10 | 0.12 | 0.18 | 0.30 | 0.44 | 0.63 | 0.72 | 0.81 | 0.87 | 0.91 | 0.94 | 0.97 |

| A24mm | 0.70 | 0.67 | 0.14 | 0.24 | 0.29 | 0.41 | 0.69 | 0.80 | 0.87 | 0.94 | 0.96 | 0.94 | 0.88 | 0.86 |

Product Care

Handling & Storage

Handle products with care to avoid folding the polyester felt, chipping its edges or indenting its faces.

Store products in their original conta,iners in a well-ventilated area until the intended application environment is ready for installation. Aiiow products to acclimatize to environmental conditions. Lay them flat on their faces; do not stand them on their edges. Protect from moisture, heat, direct sunlight and the elements.

Maintenance

Lightly brush or gently vacuum to remove dust from polyester felt. Clean with warm water and mild, non-toxic soap to remove spills. Test solution on an inconspicuous sp,ot before applying to more visibl’e areas. Blot with a dry cloth after applying the solution to avoid saturating the material. Avoid applyingitoo much pressure when cleaning the products.

Warranty

Pro Acoustic Designs Inc. warrants the construction aind finish of all our products to be free from defects in material and workmanship for a period of year from the date of purchase.

Colours

Available in 12,24 mm